Your brand, your products, our expertise.

From concept to shelf, Kutol will guide the contract manufacturing process to create your over the counter (OTC) or cosmetic skin care products. Our 100+ year history in the away-from-home skin care industry lends itself to make this process as efficient as possible – ensuring speed to market, high quality hand care products and full compliance with FDA regulations.

Kutol's Contract Manufacturing Capabilities

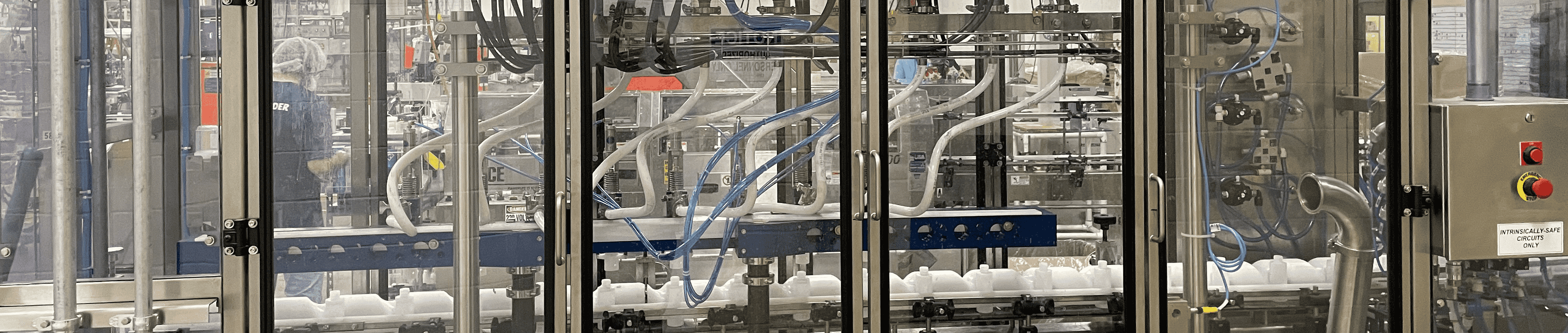

Filling Capabilities

One ounce to tankers

Thin to thick; water, oil, alcohol based materials

Bottles or bags

Inline label application

Inline check weighers

Sonic welding capability

Unique pump/cap application

In application 1 5/8″ or 2″ diameter plastic tubes

Efficient Packaging and Shipping

Custom or standard packaging

Tanker trucks, drums, totes, pails, gallons

Oval, round, square, angle-necked, F-style bottles

Packaging validation provided

Facilitate shipping options through all major carriers

Traffic coordination and support: truckload, LTL, teams, tankers